Harsh competition in the dental industry is seen to force manufactures to outsource production to countries outside of Europe to mitigate increasing costs. However, XO CARE has continued to stay true to its origins by keeping part of the manufacturing process in-house, especially the scaler production, whereas a wide range of Danish sub-suppliers, amongst those Ceropa A/S and Brandt A/S are supplementing the unit production process.

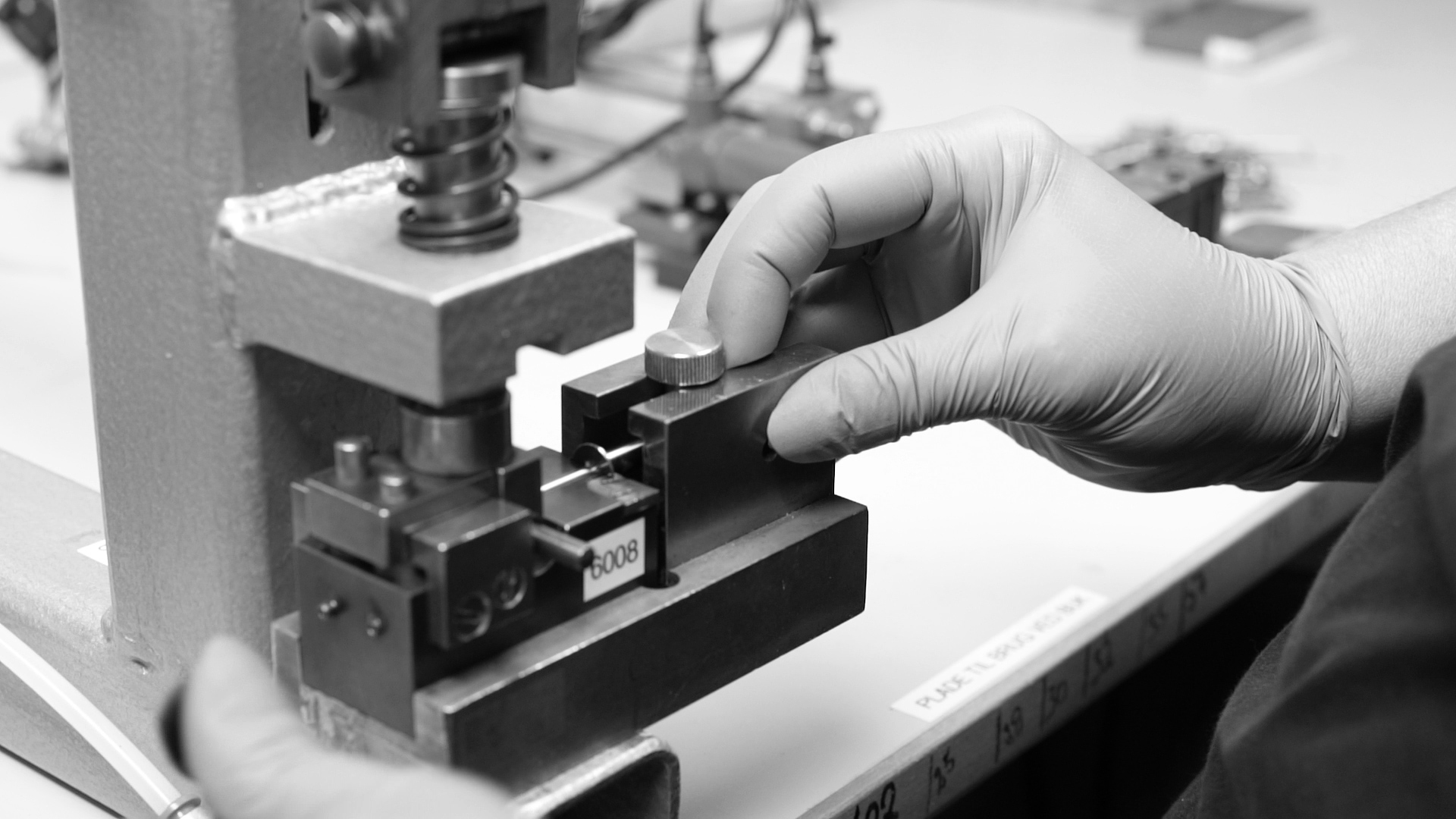

Visiting customers often express great surprise when discovering that the XO units are fully assembled, quality checked and manually tested in our production department in Hørsholm, Denmark. This is also where an entire section is dedicated to the production of XO ODONTOSON 360 scaler instruments, famously made of titanium, turned in CNC machine, and finally adjusted to meet performance requirements - by hand. Afterwards, every tip is stress-tested for optimum lifetime.

Torben Hansen, XO’s Chief Operational Officer, explains: “Although we do not have the capacity for mass production, XO instead takes pride in satisfying customer demands and ensuring extraordinary quality in every delivery.”

Torben moves on to point out some of the benefits of being a relatively small, family-owned company:

‘’Supply chain management, securing that we have all parts available for the planned production and lean warehouse management is key to maintaining our steady workflow. Working with XO CARE – given the size of the organization - means that we have a short way of communication and decision making. This enables us to react fast to any consumer request; changes or challenges we meet.’’

Reference is made of course to the Corona pandemic where it has been necessary to demonstrate agility and to instantly react to changes, e.g. disruptions in delivery of materials and a temporary drop in order intake when many dentists were instructed to close their practises for a while. “But that has only encouraged us to further streamline and upgrade our inhouse manufacturing operation”, Torben continues.

‘’Our main goal in the Operations Department is to continuously adapt our production capacity to be able to swiftly respond to the demands from our customers. For that we are also depending on our very loyal and highly qualified employees to ensure best quality. I am happy to say, that since summer of 2020 we have been upscaling our production capacity every month, quite consistently.’’

Danish quality design and manufacturing expertise is known world-wide; XO CARE is proud of being part of that legacy.

XO CARE collaborates with advertisers, media agencies, and networks. The purpose of such cookies is generally to ensure the delivery of targeted online ads on behalf of our collaborative partners and Therefore, the following companies also place session or persistent cookies on our website: Google and Facebook. Privacy and cookie policy.