Please note: These technical specifications correspond to XO FLOW version 1.1.

As described below XO FLOW is an upgradable platform and various software upgrades, new functions and new instruments are planned.

XO FLOW (REF FL-001) is a digital dental unit platform with workflow guidance and dental apps.

Over-the-patient delivery unit with balanced instruments for working:

- Right-handed in duo – or solo

- Left-handed in duo – or solo

The unit is fitted with:

- a built-in computer

- a network connection (the network connection will be active in a future software version – see details here).

- Dashboard: Touch activated graphical user interface for dentist and chairside assistant – integrated with the instrument bridge - for controlling and monitoring the unit and attached instruments

- Navigator: Touch sensitive screen with dental apps

Integration with other dental devices and software solutions connected to the network (available in a future software version – see details here).

Multi-user network solution – where all users can access their own settings from any unit in a network (available in a future software version – see details here).

20 years’ service life - see details here.

XO FLOW characteristics:

- Upgradable

- Design based on standardized technologies, components and platforms

- Instrument modules

- Dashboard and Navigator prepared for new display panels

- Built-in computer may be upgraded to new computer generations

- Designed with smooth and easy-to-clean surfaces. Metal parts painted using an antimicrobial powder coat – a combination of agents with nanoscale silver gives a long-term protection against formation of bacteria and fungi on the surfaces.

Only materials and components of highest quality are used.

All materials in contact with patient and/or operator are in accordance with EN ISO 10993-1 (biological evaluation of medical devices).

Designed and manufactured in Denmark.

Two design awards:

- Red Dot, winner 2021, Medical devices and technology

- Red Dot, winner 2021, Innovative products

Please note: XO FLOW Patient chair must be ordered separately!

XO FLOW unit with lifting mechanism for XO FLOW patient chair – incl. all features described in section 1 (FL-001)

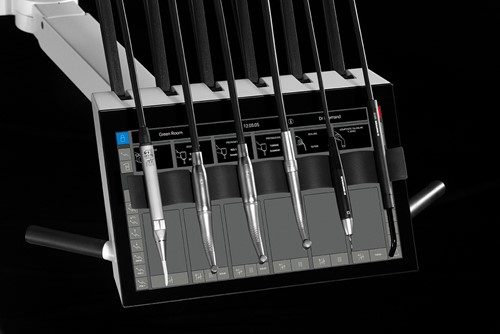

Centrally placed instrument bridge with integrated Dashboard:

- Touch activated 17” HD screen

- Laminated, anti-reflex “Gorilla” glass fitted with a protective steel frame

Up to six instrument modules:

- of any type

- and in any order

- may be fitted into the instrument bridge

The instrument bridge features:

- Individually balanced instrument suspensions

- Force to move the instrument bridge corresponds to: 400 g – 1,500 g

- Shielded” unit instruments (instrument tips cannot touch patient’s chest)

- Detachable instrument and hoses

- Detachable instrument suspensions

- Detachable instrument holder fitted with magnets

- Detachable instrument holder pad

- Detachable handles

- Preparation for up to two click-on tray holders

- Speaker with adjustable volume

- Flexible bridge arm

- Working position (centrally over the patient’s chest)

- Parking position (at the 3 o’clock position)

- Air instrument return air oil separator

- Optional Dashboard protection foil (see details here)

Please note: If less than 6 instrument modules are attached, one or more blind modules (see section 3.6) must be fitted.

Each instrument consists of:

- Instrument with hose and plug

- Instrument module with electronics and valves etc. needed to control the instrument

Advantages of using instrument modules:

- Instruments may be positioned in any sequence

- Electrical fault confinement meaning increased uptime

- Easy field replacement of defective modules

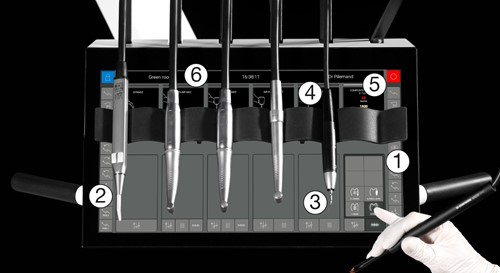

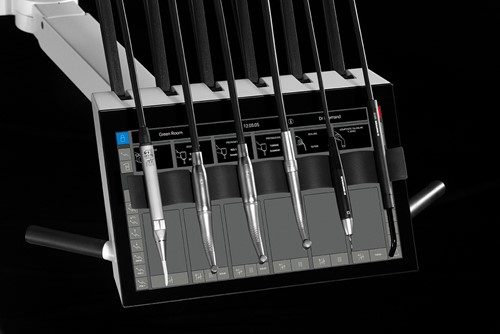

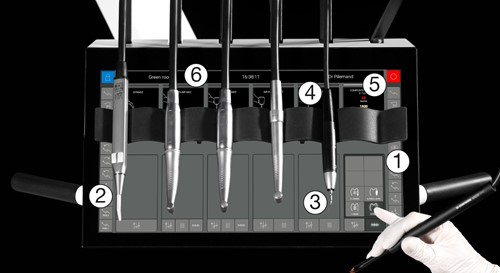

Dashboard with graphical user interface for monitoring and controlling unit instruments for both dentist and chairside assistant with:

- Side buttons for (right-handed) dentist (1) – of which eight are configurable – for controlling unit and patient chair

- Side buttons for chairside assistant (or left-handed dentist) (2) – of which eight are configurable – for controlling unit and patient chair

- Six instrument control windows (3) – one for each instrument – operated with one-motion-control (little finger of instrument holding instrument)

- Six instrument displays (4) (one for each instrument depending on the situation):

- Icon and name of instrument

- Maximum or actual value of the primary parameter (e.g. speed) and if applicable the secondary parameter (e.g. torque)

- Name of preset

- Selection of contra angle, bur etc. to match preset

- Name of workflow and step incl. parameters (e.g. exposure time and radiant exitance)

- Six instrument selection indicators (5)

- Information bar (6) with time, name of current operator, name of operatory and notifications (if any)

- Asepsis control menu at shutdown and start up

- Lock Dashboard function for cleaning of Dashboard

- Texts in EN, DE, FR, and DK

Each instrument control window may assume up to four different states:

- Closed

- Preset

for selection of optimal instrument settings (e.g. speed, torque, spray) targeted at performing a specific procedure (e.g. preparation of a filling or excavation) with one tap

for selection of optimal instrument settings (e.g. speed, torque, spray) targeted at performing a specific procedure (e.g. preparation of a filling or excavation) with one tap

- Up to eight presets per type of instrument

- Standard presets

- Individually configurable presets

- Workflow

for execution of a sequence of steps with optimal instrument settings in each step for:

for execution of a sequence of steps with optimal instrument settings in each step for:

- Composite restorations

- Endo preparation

- Standard workflows

- Configurable workflows (using the Administration app)

- Adjustment

with sliders and buttons for monitoring and adjusting instrument settings

with sliders and buttons for monitoring and adjusting instrument settings

- Six-way syringe:

- Air instrument (turbine):

- (Maximum) speed

- Spray water: On/off and amount of spray water

- Spray air: On/off and amount of spray air

- Automatic chip blow: On/off

- Micromotor:

- (Maximum) speed

- Spray water: On/off and amount of spray water

- Spray air: On/off and amount of spray air

- Tactile function (limitation of torque): on/off

- Automatic chip blow. On/off

- Ultrasonic scaler:

- (Maximum) amplitude

- Irrigation water: On/off and amount of spray water

- Composite curing light:

- Radiant exitance

- Exposure time

Foot control that is easy to understand and use with:

- Pedal (1) for start/stop and if relevant adjusting the primary instrument parameter

- Joystick (2) for operating patient chair

- X (3) and O (4) buttons for operating programable chair positions

Configuration: Function of pedal, joystick, X and O buttons may be configured individually – to for example resemble the function of classic XO/FLEX units.

Configuration: Function of pedal, joystick, X and O buttons may be configured individually – to for example resemble the function of classic XO/FLEX units.

Floor cleaning position: Rilsan® coated foot control hanger.

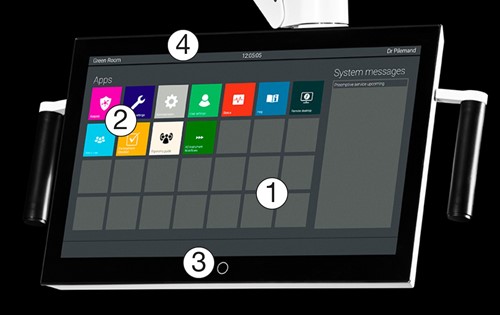

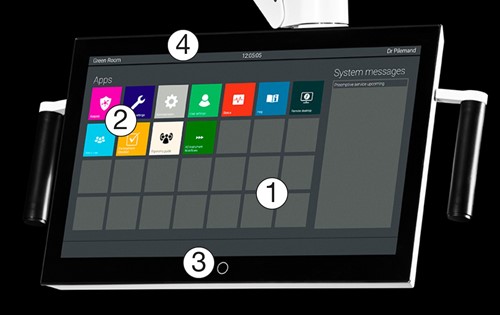

Touch activated 17” HD screen with laminated, anti-reflex “Gorilla” glass fitted with a protective steel frame with a long articulating arm for positioning Navigator:

always within the field of peripheral vision

The Navigator is equipped with:

- Detachable handles

- Home page (1) with apps (2)

- Home button (3)

- Virtual keyboard

- Information bar (4) with time, name of current operator, name of operatory and notifications (if any)

- Texts in EN, DE, FR and DK

Administration app

- Access is pin code protected

- Create and delete users

- Configuration of

- Instrument workflows

- Dashboard side buttons

- Power settings

- Cup filler and cuspidor

- Time and date

- Language

- Treatment room name

- Sound and volume

User settings app

- Configuration of user settings:

- Instrument presets

- Instrument settings

- Foot control

- Programable patient chair positions

- Light

- Power

- Cup filler and cuspidor

- Automatic functions (for example automatic cuspidor flush when chair reaches programmed position)

- User settings are automatically replicated to and accessible in all XO FLOW units connected in a network2

Select user app

- Each user can retrieve own unit and instrument settings on all XO FLOW units connected in a network2

- Unlimited number of users

Remote desktop app (available in a future software version – see details here).

- The remote desktop app makes it possible to use the Navigator for displaying and interacting with a remote Windows computer connected to the same network (but not necessarily in the same room) as the unit

- This includes, but is not limited to, PMS systems, imaging system and scanning software

See details here.

Instrument workflow app

- Selection of instrument workflows for:

- Micromotors – endo workflows

- XO ODONTOCURE – composite restorations

Pretreatment checklist app

- Short instruction films demonstrate the intended use of XO FLOW

Ergonomy guide app

- Instruction on how to position patient and operators in relation to tooth/tooth surface to be treated to sit and see well – at the same time

Help app

Status app

Asepsis app

- Manual activation of water and suction line disinfection procedures

Technical settings app

- Setup of the unit (access for authorized service personnel only)

Arms for instrument bridge, Navigator, and operating light are pivoting on one vertical column.

All arms:

- Are manufactured in aluminum and connected via slim joints with roller bearings

- Have adjustable and maintenance-free balance spring and friction brakes for smooth and effortless operation

- Have steel covers fitted with magnets

The unit stand:

- Is manufactured in steel and aluminum

- Has service panels for easy access to XO Water disinfection, XO Suction disinfection, and auxiliary connections

- Has detachable aluminum side covers for easy service access

- Has buttons located on the top of the unit stand for patient activation of cuspidor flush and cup filler (not for units without cuspidor and cup filler)

The cuspidor is fitted with:

- A detachable and thermodisinfectable cuspidor bowl in glass with a gold trap

- A protection disc

- A stainless-steel faucet:

- For efficient rinsing of cuspidor bowl

- With swivel function and automatic cut off of water supply for easy removal of cuspidor bowl for cleaning

Rinsing time cuspidor: 5- 30 seconds

Gold trap mesh size: < 2 mm

The cup filler includes:

- A detachable and thermodisinfectable cup holder

- A stainless-steel faucet for cup filler

Amount of water to cup filler: 10 – 30 cl

Please note: XO FLOW is available without cuspidor and cup filler, see details here.

The unit’s water system includes:

- A main water valve for automatic switching incoming water on/off

- A filter for incoming water (50 μm)

- Maximum inlet water conductivity: 850 µS/m

- Media separated solenoid valves for high uptime and low service costs

- Servo control of solenoid valves for spray/irrigation water, flowmeter diameter 0,7 mm

- Fittings approved for use in the food industry

- Water container with backflow prevention ensuring a vertical air gap of 20 mm to prevent procedural water from flowing back into the municipal water supply system

- Leakage sensor providing automatic shut-off of water supply if an internal water leak is detected

- Integrated water softener:

- Decarbonizes water

- Protects internal components by reducing the limescale content

- Improves taste of water

- Water cartridge replacement notification to the Navigator

- Water softener cartridge accessible via service panel and replaceable without use of tools

Automatic two-step procedure:

- In the evening:

- Water is emptied from the water system

- Disinfection of suction

- After about 7 minutes the unit shuts down automatically

- In the morning:

- Automatic disinfection of the water system

- The intensity depends on the time elapsed since the last successful disinfection cycle

- The unit will be ready for use after about 10 minutes depending on the instrument configuration

Manual function:

Manual function:

- In addition to the automatic function, water disinfection procedures and flushing of the unit’s water lines with water may be managed using the Asepsis app.

Notification:

- Replacement notifications concerning XO Water disinfection cartridges and XO Suction disinfection cartridges shown on the Navigator.

XO Water disinfection system:

- Keeps the number of microorganisms in the unit at a level suitable for drinking water

- Hinders limescale from forming by binding the calcium carbonate

Function:

- Continuously dispenses a solution of non-toxic disinfectant containing hydrogen peroxide to the procedural water

- Automatic two-step procedure in the evening and in the morning (see details here).

- Quick replacement by the users of the disinfection cartridge holder through a service panel

Supplied with a water disinfection instrument holder.

For details concerning XO Water disinfectant go here.

Please note: XO Water disinfection cartridges must be ordered separately.

Hardware:

- Mains switch at the base of the unit stand

- Easily accessible on/off switch at the rear side of the unit stand

- Integrated computer

- CAN bus architecture that ensures high product reliability

- LAN/internet connection: Two wired ethernet ports

- Extensible hardware platform

Software:

- Windows 10 based

- Shutdown switch on Dashboard

- Automatic and configurable stand-by mode

- Configurable automatic power down function

The unit’s air system includes:

- Main air valve: Automatic switching incoming air on/off

- Filter for incoming air (5 μm)

- Sensors for monitoring pressure

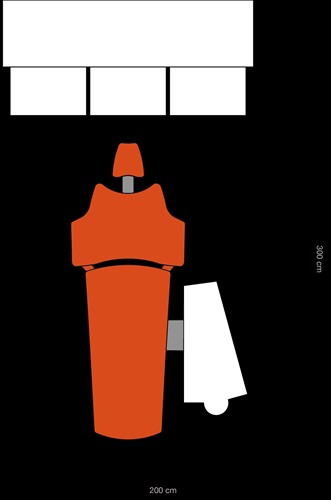

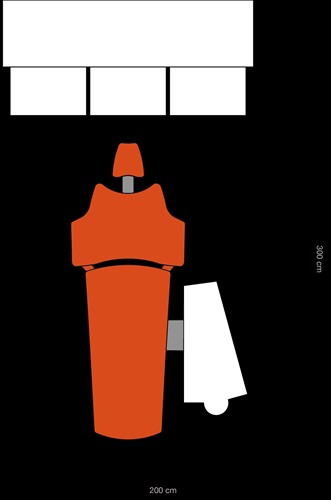

Minimal room size (XO FLOW unit + XO WORKTOP):

- Width: 200 cm (recommended 220 cm)

- Length: 300 cm (recommended 320 cm)

- Ceiling height: > 230 cm (recommended 255 cm)

Electrical and other installation requirements:

-

See instructions for use here

-

See installation instructions here

-

See installation plan 1:20 here

-

See installation plan 1:1 here

XO FLOW is to be maintained as prescribed in Instructions for service here.

When it is time for service, a service notification is shown on the Navigator.

One month after the installation a first service checkup should be done by a certified technician.

After that preventive service checkup is to be performed by a certified technician at intervals of 24 months.

Service each 2nd year

Including checkup and exchange of parts contained in the bi-yearly service kit – expected labor time: 1.75 hours.

Service each 6th years

6 years, 12 years and 18 years after installation a service checkup and exchange af parts contained in 6-years service kit is necessary in addition to the work related to the bi-yearly service.

Operating conditions:

- Temperature: +15oC – +35oC

- Relative humidity: 20% – 95%

- Air pressure: 700 hPa – 1060 hPa

- Installation altitude: Max. 2,000 meters above sea level

Transport and storage conditions:

- Temperature: -40oC – +70oC

- Relative humidity: 10% – 95%

- Air pressure: 700 hPa – 1060 hPa

Color of unit base: XO Silver (IGP 6802/gloss 20).

Color of unit column: XO Silver (IGP 6802/gloss 20), Traffic white (RAL 9016/gloss 20).

Color of stand, arms for bridge, light and screen, instrument bridge and operating light: Traffic white (RAL 9016/gloss 20).

Color of handles, instrument bridge pad, suction, foot control and other details: Black grey (RAL 7021).

Please note: Minor differences in color of different parts of the product may occur due to different materials and different paint processes.

Please note: Exposure to sunlight may change colors over time.

Traffic white (RAL 9016/gloss 20) (XB-935)

with column in XO Silver (IGP 6802/gloss 20)

IGP 6802 RAL 9016 RAL 7021

Note: Slight color differences may occur.

XO FLOW is a platform for the future, prepared for

- Intraoral video camera module

- Camera app

- Imaging app

- Remote technical diagnostics

- Remote software update

- USB connection in instrument bridge

- Reciprocal endo feature

- Apex locator

- Surgical motor module

- Peristaltic pump

- Instrument workflows for implants

- XO ODONTOSON module with perio solution

- 3rd suction hose

- 230 V power connection

- Timer and alarm app

- User statistics app

- Automatic documentation of disinfection procedures

- User statistics: E.g., number of patients and duration of treatments

- Extended workflow-solutions

See more details here.

2022-05-09/KS/TLT

Configuration: Function of pedal, joystick, X and O buttons may be configured individually – to for example resemble the function of classic XO/FLEX units.

Configuration: Function of pedal, joystick, X and O buttons may be configured individually – to for example resemble the function of classic XO/FLEX units.

Child cushion, Grey skai (XO-813)

Child cushion, Grey skai (XO-813)