XO FLEX (REF CF-200) is a dental treatment unit with:

- A compact floor-mounted unit stand with lifting mechanism for XO Patient chair (side lift)

- A cuspidor

- A single-column pivoting articulated balanced arms for instrument bridge, operating light and display

- The unit is designed with over-the-patient delivery of unit instruments for working primarily on supine patients in order to obtain healthy working conditions and efficient workflow.

The user interface is yielding maximum focus on the oral cavity and optimal infection control.

Please note: XO Patient chair must be ordered separately!

XO FLEX unit with lifting mechanism for XO Patient chair (XO-102)

XO FLEX unit without lifting mechanism for standalone 3rd party patient chair (XO-836)

The unit stand is manufactured in steel and aluminum with:

- Service panels for easy access to XO Water disinfection, XO Suction disinfection and auxiliary connections

- Detachable aluminum side covers for easy service access

- Two buttons located on the top of the unit stand for patient activation of cuspidor flush and cup filler

All incoming water is filtered (50 μm), eliminating particles from main water supply.

Incoming compressed air is filtered (5 μm).

A main water valve automatically switches water on/off when activating the main switch. A leakage sensor provides automatic shut-off of water supply if an internal water leak is detected.

An integrated water softener decarbonizes water for use in the XO unit and protects the internal components of the unit by reducing the limescale content. Furthermore, the taste of the water is improved by removing unpleasant odors and tastes, e.g. chlorine.

Detachable and thermodisinfectable cuspidor bowl in glass with gold trap. Swiveling stainless steel faucet with safety switch allowing easy removal of cuspidor bowl for cleaning. Detachable and thermodisinfectable cup holder and stainless steel faucet.

Arms for instrument bridge, operating light and XO HD Display pivoting on one vertical column. Arms manufactured in aluminum and connected via slim joints with roller bearings. Adjustable and maintenance-free balance spring and friction brakes for smooth and effortless operation. Steel covers fitted with magnets.

Fitted with up to six detachable unit instruments:

- The 3-/6-function syringe is placed to the left (near the dental assistant) or to the right (unit for left-handed dentists)

- All other unit instruments may be placed as required by the end users

- When ordering the unit please specify where the different instruments should be placed

- After delivery it is possible for a technician to rearrange the instruments on the bridge

The instrument bridge is supplied with:

- A detachable instrument pad

- A detachable bridge protection pad

- Two autoclavable handles

- A display

- A speaker with adjustable volume providing acoustic signals to the operator

- A programming button

The instrument bridge is prepared for a hand-instrument table.

Depending on the weight of the instrument, the instrument suspension is individually adjusted for optimal balance.

All unit instruments are fitted with a plug and may be attached/detached by the users for cleaning and disinfection – without using tools.

At the front of the instrument bridge a display for monitoring instrument data is fitted. The light intensity of the display text field is adjustable.

The display consists of:

- One 8-digit text field: Indication of the maximum preset value of the primary instrument parameter (for example speed) when the instrument is lifted forward, but not activated – and the current value of this primary parameter when the instrument is activated

- Three green LEDs for indication of selected amount (three levels) of spray water or for spray water off

- One blue LED: Indication of spray air on/off

- One white LED: Automatic chip blow enabled/disabled

All functions of XO FLEX Unit, patient chair and instruments are controlled hands free using the foot control and/or chair base joystick.

The foot control is fitted with a pedal and joystick.

When all unit instruments are at rest the foot control manages functions related to the unit and chair etc.

When a unit instrument is lifted forward the foot control manages this active instrument.

The pedal can be activated in three directions (left, right and down).

The joystick can be activated in four directions (north, east, west and south).

In addition, the foot control is equipped with two activation buttons and a hoop in stainless steel.

Speed control method: Variable.

Selection between three (maximum) speed levels in the range 100 – 40.000 RPM + 20%.

Speed (power) control method: One-step.

Selection between three speed/power levels.

The amount of spray (irrigation) water and air is controlled electronically using proportional solenoid valves.

The spray water may be adjusted in the range: 10 – 70 ml/min ± 20% depending on the dimensions of the spray pipes in the attached instruments.

Spray air can be set between 0 – 100% of maximum.

Short blast of high-pressure chip air each time an instrument with spray water stops. Keeps the preparation dry and helps the operator focus on the work task.

Control method: One-step.

With selection between three power levels.

Irrigation water for scalers may be adjusted in the range: 10 – 90 ml/min ± 20%.

Selection between three irrigation water levels (and no irrigation).

In addition to the foot control, a chair base joystick for controlling the patient chair is fitted.

The following optional automatic functions are available:

- Operating light on/off automatically when the patient chair reaches/leaves working position

- Cuspidor rinse starts automatically when cup filler stops

- Cuspidor rinse starts automatically when the patient chair reaches the rinse position

All XO FLEX functions are software controlled.

Latest software (firmware) version is 4.02, released 2017-03-02.

- Patient chair: Position 1 and 2 as well as rinse position

- Micromotor:

- Maximum speed (3 levels)

- Amount of spray water (3 levels)

- Amount of spray air (% of maximum)

- Air instrument (turbine)

- Speed/power (3 levels)

- Amount of spray water (3 levels)

- Amount of spray air (% of maximum)

- Scaler:

- Power (3 levels)

- Amount of irrigation water (3 levels)

- Light curing lamp: Curing time (3 selections) and soft start

- Peristaltic pump: Selection of instrument to be attached

- Cuspidor flush: Time

- Cup filler: Time

- Enable/disable automatic operating functions of:

- Cup filler

- Cuspidor

- Operating light

- Enable/disable control of operating light with foot control

Left-handed configuration is obtained by fitting the:

- 3- or 6-function syringe on the right side of the instrument bridge

- The XO Ambidex suction hose holder enables you to work right-handed, left-handed, SOLO, or in DUO

XO Water disinfection continuously dispenses a solution of non-toxic disinfectant containing hydrogen peroxide to the procedural water. The disinfectant is proven to keep the number of microorganisms in the unit at a level suitable for drinking water and it hinders limescale from forming by binding the calcium carbonate.

XO Water disinfection is supplied with a disinfection instrument holder.

The users are notified on the instrument bridge display when the level of disinfectant is low.

The cartridge holder is accessible from the outside through a service panel and allows for quick replacement of disinfection cartridges by the users.

Two types of disinfection routines are available:

Overnight disinfection:

- At the end of the workday the water container and unit’s waterlines are emptied

- At the beginning of the next workday the water container is filled and the unit water lines are flushed with disinfectant

Intensive disinfection for use after weekends, holidays, or longer periods where the unit has not been used:

- The water tank is emptied

- The water tank is filled again using a double dose of disinfectant

- The unit water lines are flushed with a double dose of disinfectant

For details concerning XO Water disinfection, cartridges see here.

Please note: XO Water disinfection cartridges must be ordered separately.

The backflow prevention provides a vertical air gap of 20 mm for preventing procedural water from flowing back into the municipal water supply system.

It contains a water tank with a capacity of approx. 1 liter that provides pressure to the water that has passed through the air gap. The water tank is filled when there is no demand for procedural water.

A suitable method for preventing contaminants from flowing back into the municipal water supply is required by law within the EU. Without the backflow module the XO unit does not fulfill the requirements of ISO 7492-2 and EN 1717

XO FLEX is designed with smooth and easy-to-clean surfaces.

Metal parts of XO FLEX are painted using an antimicrobial powder coat. A combination of agents with nanoscale silver gives a long-term protection against formation of bacteria and fungi on the surfaces.

The unit is supplied with autoclavable handles, suction nozzles, cover for instrument holder, and XO Patient tray.

Other XO FLEX features that enhance asepsis and reduce environmental footprint:

- Hands-free user interface

- Automatic chip blow

- XO Water disinfection

- Backflow prevention

- XO Suction disinfection

- Automatic functions

All surfaces and XO Comfort fabric may be disinfected and/or cleaned with:

- XO Intensive disinfection – for disinfection of all surfaces – 6 x 1 liter (AP-831)

- XO Gentle disinfection – for disinfection of sensitive surfaces – 6 x 1 liter (AP-832)

- XO Fabric makeup – for cleaning and care of fabric surfaces on patient chair and operators’ seats – 1 x 0,5 liter (AP-833)

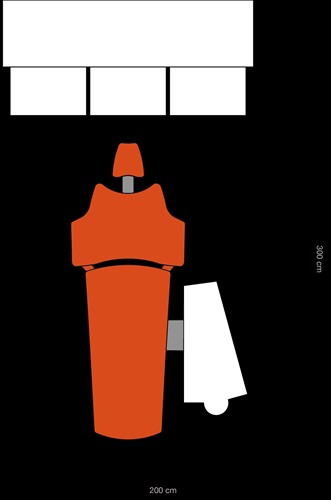

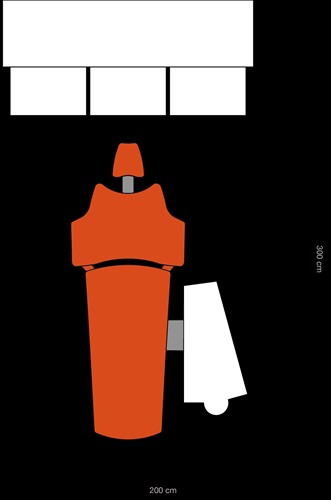

Minimal room size (XO FLEX unit + XO WORKTOP)

- Width: 200 cm (recommended 220 cm)

- Length: 300 cm (recommended 320 cm)

- Ceiling height: > 230 cm (recommended 255 cm)

Electrical and other installation requirements

- See Instructions for use here.

- See installation plans YC-001 (1:1) and YC-002 (1:20) here.

XO FLEX is to be maintained as prescribed in Instructions for service.

When it is time for service a message is displayed in the bridge display.

A preventive service checkup is to be performed by a certified technician at intervals of 12 months.

A Service

Including checkup and exchange of parts contained in A service kit – 12 months, 36 months etc. after installation – expected labor time: 1,5 hours

B Service

Including checkup and exchange of parts contained in B service kit – 24 months, 48 months etc. after installation – expected labortime: 3,5 hours

C Service

Each 6th after installation a service checkup and exchange af parts contained in service kit C is necessary in addition to the work related to B Service – expected labor time (B + C service): 5,5 hour in total.

Operating conditions:

Temperature: +15°C – +35°C

Relative humidity: 20% – 95%

Air pressure: 700 hPa – 1060 hPa

Transport and storage conditions:

Temperature: -40°C – +70°C

Relative humidity: 10% – 95%

Air pressure: 700 hPa – 1060 hPa

XO FLEX is designed for use by dentists and other qualified personnel for prevention and treatment of human teeth diseases.

XO FLEX Unit:

- Is in compliance with relevant requirements concerning class IIa equipment in Council Directive 93/42/EEC on medical devices

- Has been developed, manufactured, and handled in accordance with ISO 13485

- XO FLEX fulfills requirements of:

- EN 60601-1

- EN 60601-1-2

- EN 1640

Color of unit base: XO Silver (IGP 6802/gloss 20).

Color of unit column: XO Silver (IGP 6802/gloss 20), Traffic white (RAL 9016/gloss 20).

Color of stand, arms for bridge, light and screen, instrument bridge and operating light: Traffic white (RAL 9016/gloss 20).

Color of handles, instrument bridge pad, suction, foot control and other details: Black grey (RAL 7021).

Please note: Minor differences in color of different parts of the product may occur due to different materials and different paint processes.

Please note: Exposure to sunlight may change colors over time.

Traffic white (RAL 9016/gloss 20) (XB-935)

with column in XO Silver (IGP 6802/gloss 20)

IGP 6802 RAL 9016 RAL 7021

Note: Slight color differences may occur.

Instruments and service kit supplied with XO ODONTOSON 360

Instruments and service kit supplied with XO ODONTOSON 360